SERVICES :

INK MIXING

Mixing of solvent based inks is performed by computer controlled system Inmaker. Water based ink are mixed on a similar, semi-automatic mixing machine. We produce required inks according Pantone guide or other requirements. The goods will be delivered within 48 hour since received order (see contact us).

|

|

|

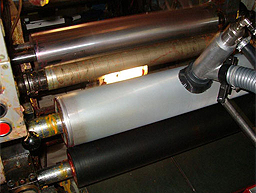

ANILOX ROLLS

We supply cleaning substances for daily maintanence of anilox rolls and their expert cleaning by our workers. We offer possibility to clean rolls directly in print-press in customer or our premisses. This support includes measurement of ink transfer by anilox roll and optical check of anilox roll.

Usage of NaHCO3 for cleaning of anilox rolls using dry process allows it's surface cleaning without any damage (scratching). The cleaning process was developed by expert anilox roll manufacturers, and it originated from requirements and needs of users of print equipment. The major benefits of our cleaning system are:

- homogenous cleaning of whole roll surface using special cleaning nozzle. This nozzle is kept in radial direction and precisely set distance from roll surface.

- grid cells are not damaged by cleaning - fine particles of cleaning powder are used to remove dry ink from cells,

- it can be used for various kinds of rolls (variable length etc.),

- fast instalation of cleaning device and simple manipulation,

- possibility to control cleaning process during operation,

- low energy requirements and multiple usage of cleaning powder,

- ecologically friendly cleaning system – without any harmful or contaminating materials for environment.

Important advantage of this system is possibility to clean anilox rolls directly in our customer premisses without need to dismantle rolls from printing-press.

|

|

|